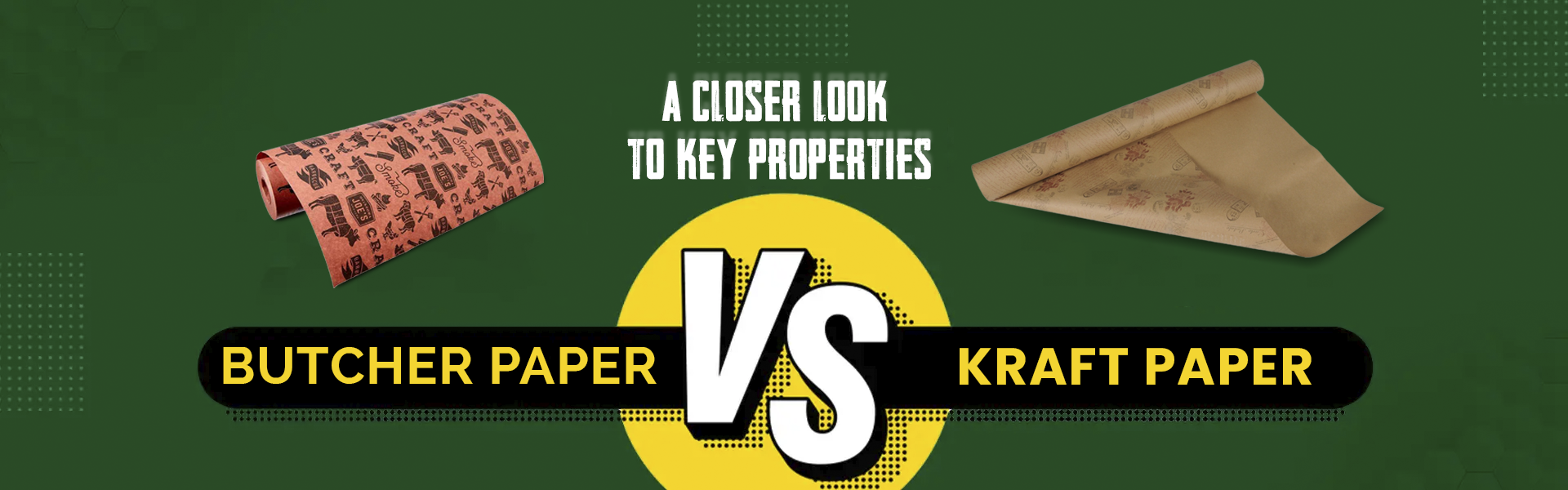

Butcher Paper vs. Kraft Paper: A Closer Look To Key Properties

March 18, 2025 Uncategorized

Butcher and kraft are two common papers used in the food industry. Brands that are looking for sustainable and sturdy packaging prefer this paper. Although both of them differ significantly their mechanical and chemical properties vary significantly.

The similarity in the appearance of the paper makes it difficult for the users to understand the difference. In this blog, we will discuss the features that vary in both of the papers.

Chemical Differences

In butcher paper, special treatment chemicals are applied such as sizing agents. Apart from this, in some cases, butcher sheets can also be coated with wax or polyethylene coatings that increase the paper’s capability to resist moisture.

On the other hand, kraft paper is generally used untreated without the application of sizing agents and coatings. However, if a brand demands, sizing agents can be applied to enhance the moisture resistance ability of the kraft paper sheets.

Mechanical Differences

When it comes to the mechanical difference, butcher paper is much more durable and flexible and it can be wrapped around meat without tearing. When it comes to kraft, it is stiffer and coarse which is why it has a better tensile strength and can be used for packing and wrapping heavy items.

Manufacturing Differences

In the manufacturing of kraft paper, a process is involved called the kraft process. This process involves the chemical pulping of the paper, here the wood chips are treated with sodium hydroxide and sodium sulfide that break down the lignin into separate cellulose fibers. The result is a strong and durable paper that is not bleached and has a rustic color. No other coatings are applied to the kraft paper rolls.

Butcher paper is manufactured by the kraft process, but it also undergoes special treatments. Apart from the application of sizing agents, wax or PE coatings are also applied to butcher sheets.

Chemicals Used In Butcher Paper Vs. Kraft Paper

Although the kraft process gives the maximum strength to both papers, nonetheless there are certain chemicals applied to butcher paper to enhance its functionality and resistant nature. The chemicals used in both the papers are as follows:

Butcher Paper

- Sizing agents alkyl ketene dimer (AKD) or rosin

- Wax or PE coating

- Bleaching agents

Kraft Paper

- Usually untreated but it can be treated with sizing agents

The table shows some of the common differences when it comes to butcher paper vs kraft paper

| Feature | Kraft Paper | Butcher Paper |

| Material | Wood pulp | Wood pulp |

| Strength | Very strong | Moderate |

| Texture | Rough | Smooth |

| Coating | Uncoated | Coated/Uncoated |

| Color | Brown | White/Brown |

| Moisture Resistance | Low | High |

| Common Use | Packaging | Food wrapping |

| Food Safe | No | Yes |

| Flexibility | Stiff | Flexible |

| Cost | Affordable | Slightly higher |

Moisture And Temperature Resistance

As on butcher paper coating is applied therefore it has a good moisture resistance. The application of sizing agents also causes the paper to resist moisture. Nonetheless, heat resistance is a variable phenomenon in different types of butcher sheets, if you have not applied any coatings on the paper then you can use it for mocking meats, on the other hand, avoid direct heat application.

Kraft paper is rarely treated with sizing agents which is why it does not have a good resistance to highly moist applications. This paper is not designed for high heat application but its durability makes it an ideal option for wrapping products.

What Is A Sizing Agent, And Can It Be Used On Kraft Paper?

As we have repeatedly mentioned let’s see what a signing agent is. It is a chemical that is used on the paper surface to reduce absorbency and improve the resistance to moisture and grease. Common sizing agents are rosin, alkyl ketene dimer, and succinic anhydride. Yes, you can use sizing agents on kraft paper as this agent enhances the moisture resistance of the paper without reducing the sustainable aspect of the packaging.

Types Of Butcher Paper

Several types of butcher paper are mainly differentiated based on color. The application and some physical properties of the butcher paper sheets vary from each other. On the other hand, the different varieties of kraft paper are due to the applied coating and the presence or absence of a bleaching process.

- White Butcher Paper: This is a standard, uncoated paper used for wrapping meat.

- Pink (Peach) Butcher Paper: Pink paper is used for smoking meat due to its breathable nature.

- Steak Paper: This is a thicker variation of butcher sheet that is used to pack meat to prevent drying.

- Gardenia Paper: This is a wax-coated and grease-resistant paper that is used when for moist food packaging but it is not suitable for heat purposes.

- Peach Treated Paper: This paper is moisture resistant and has antibacterial treatment which is why it is used to pack raw meat.

Types Of Kraft Paper

- Natural Brown Kraft Paper: This is an unbleached and strong paper that is used for packaging.

- Bleached White Kraft Paper: This paper is treated with bleaching agents and is used for craft projects.

- Colored Kraft Paper: This paper is colored after the bleaching process to get the desired shade.

Conclusion

Due to the same appearance of butcher and kraft paper confusion occurs among the minds of the user about whether these papers are alike or different. Despite a similar look, both papers have viable qualities. Butcher paper is comparatively more resistant to moisture and heat as compared to kraft paper which is coarse and dense. To get the best quality of the papers you can contact Grease Proof Paper and avail remarkable quality with lower rates.