Custom Sandwich Paper

get an instant quote

STEP 1

UPLOAD YOUR LOGO

Upload vector image file – .pdf, .png, .jpg, or .eps vector graphic.

STEP 2

DESIGN YOUR PAPER

Adjust your logo or image in the design tool on the paper and design it.

STEP 3

SELECT PAPER CHOICES

Select paper size, print color(s), white or Kraft paper, and sheet quantity.

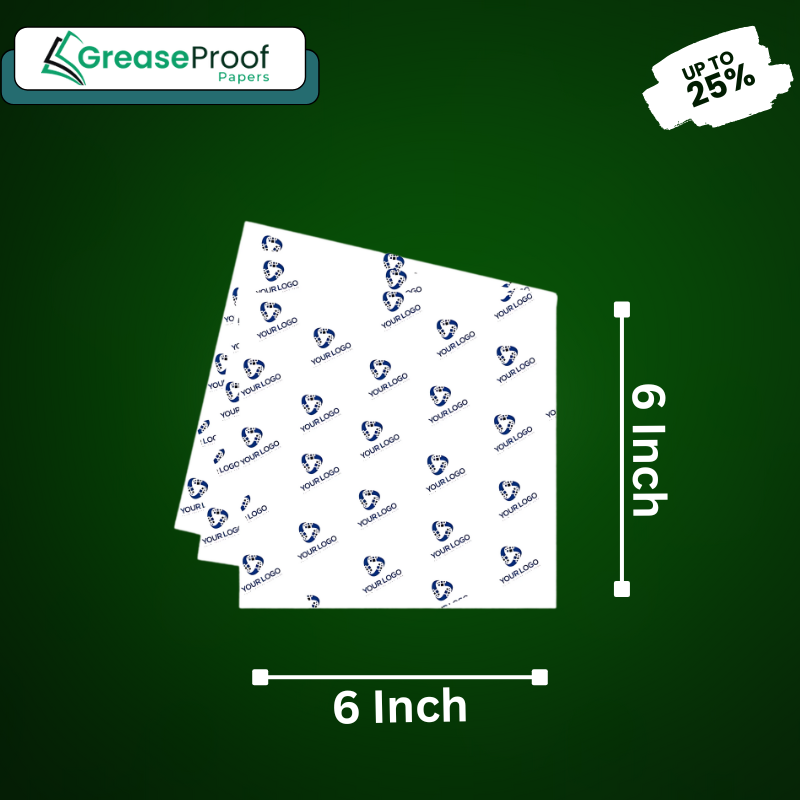

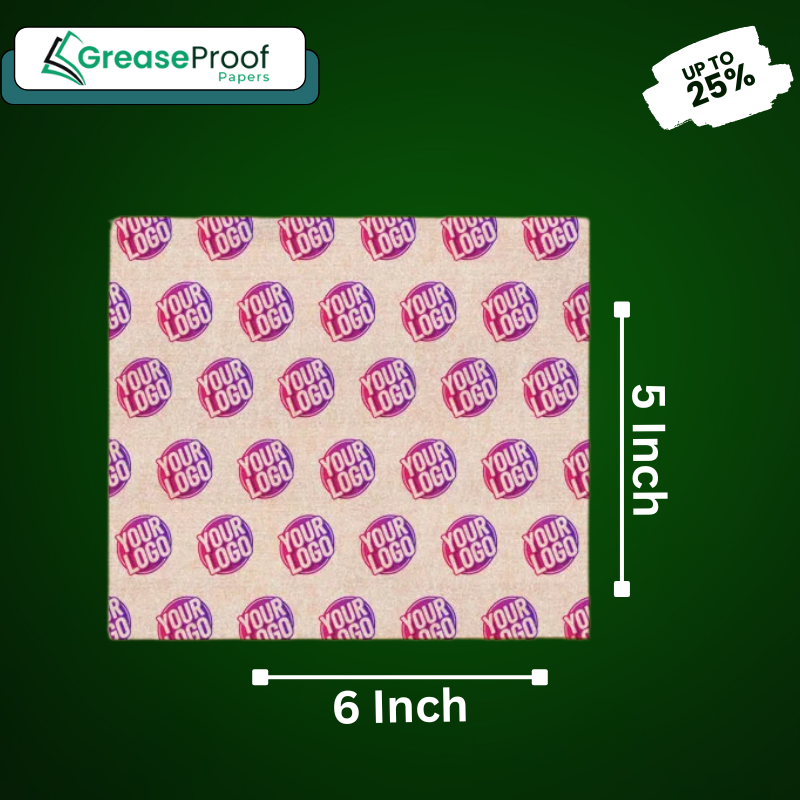

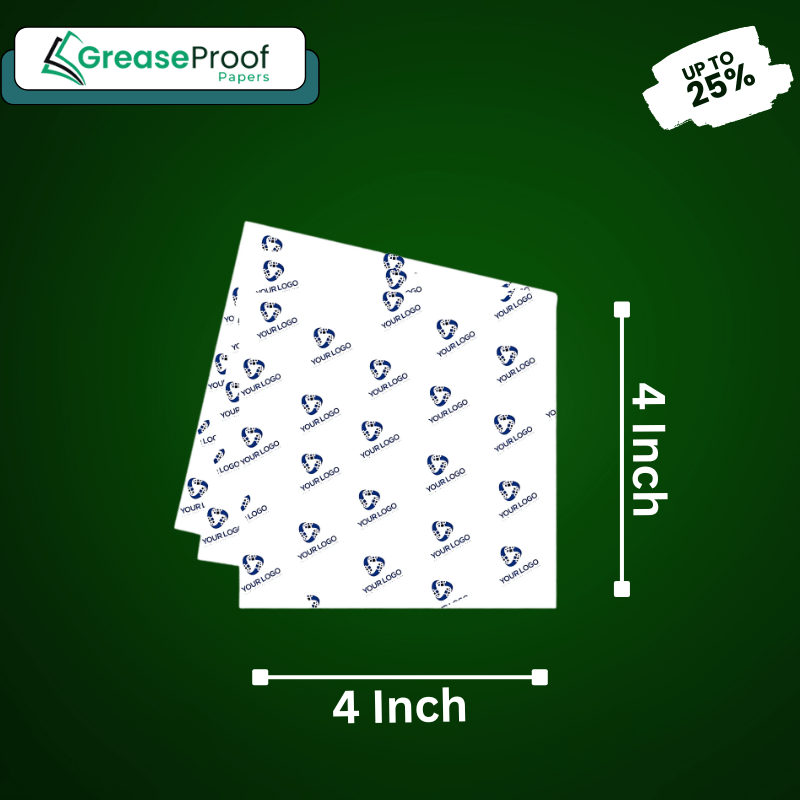

Products Size Variations

description

In the competitive food industry, where cuisines worldwide are introduced, branding is becoming crucial. Branding goes far beyond menus and storefronts, it is an entire customer’s experience and the perfection of the brand. So if you are running a deli store, a fast food corner, or even a restaurant and selling sandwiches with multiple flavors wrapped in custom sandwich paper, then you are giving yourself an edge over all your competitors.

When you wrap your sandwiches in customized papers then you not only keep your sandwiches fresh but also give your brand a unique and alluring branding tool. Restaurants that use branded custom packaging have seen almost 30 % increase in their sales. If you use custom sandwich wrap paper, you have a 72 % chance that the customers will remember your brand. Apart from this, these papers are made from sustainable materials and today 85 % of consumers prefer eco-friendly so using them is a win-win situation.

What Is Custom Sandwich Paper?

Sandwich food wrap is unique paper specifically used to cover sandwiches to keep them fresh and create an informative cover that serves as a tool for advertisement. This paper is manufactured with food-grade material which acts as a shield to stop moisture and grease from penetrating through it. It is frequently used in delis, cafes, and restaurants.

Custom printed sandwich paper can come in several styles including greaseproof or waxed and is printed with logos, designs, or promotional messages for an exciting customer experience. It is used for the packing of burgers, wraps, and any other fast food product where functionality and visibility are required. Custom sandwich paper is also recyclable and biodegradable, which helps businesses to reduce and improve their ecological footprint. Custom-made sandwich papers are a vital packaging option used in the food sector due to their functionality, branding ability, and sustainability. This paper keeps your sandwiches and snacks as fresh as you want and allows you to share your brand’s message.

Manufacturing Process

The manufacturing process of custom sandwich paper with logo consists of several steps. At our company, we use durable materials and focus on hygienic manufacturing conditions so that no hazardous element can come in direct contact with the food.

Pulping And Pressing

Pulping is the process that involves tearing the raw material into fibers within a pulping machine. These fibers are further treated to improve their adhesion characteristics of bonding. In forming the pulp is molded into thin sandwich paper sheets by a pressing of rollers. The sheets are then dried to put the moisture away. The thickness and texture of the sheets are controlled for perfection.

Surface Treatment And Coating

On sandwich wrap papers, a greaseproof or wax coating is applied to improve the functionality of the food packaging paper. These coatings prevent paper damage due to moisture or grease and give custom sandwich paper no minimum design limitation when it comes to printing.

Printing

Printing is one of the most crucial factors in the customization of paper. With the help of printing, we give a unique and alluring look to the paper along with the logo of the brand. There are multiple types of printing options in the custom food paper manufacturing sector nonetheless the best option is flexography.

The flexographic printing process employs flexible cylinders of rubber or plastics. It is particularly suitable for large-volume production runs and yields sharp and accurate designs in a shorter amount of time. The packing printing method is suitable with water-based or UV inks that are Food Contact Safe.

Why Do Not Prefer Other Forms Of Printing

In offset printing ink is transferred from a plate to a rubber cylinder, and then to the paper. Offset printing is ideal for running more copies of very detailed images or logos but the paper used may need some pre-printing treatments for better imprinting which may impact the cost of custom sandwich paper bulk.

Digital printing is utilized for smaller production volumes or intricate images, allowing for quick and cheap production. Compared to other methods it does not use printing plates which makes it well-suited for short runs. With the increase in the number of papers, the cost also increases.

Preparing The Paper For Printing

To make custom sandwich paper wholesale suitable for printing, pre-printing coatings are applied. These coatings give additional strength to the paper while giving a smooth surface that reduces the chances of paper tearing and makes it easy to get the desired design and color on the paper. The preparation steps involve:

- Sizing Agents: Paper is made from wood pulp which is why some chemical agents are added to the paper pulp to minimize the porosity of the paper and to avoid bleeding of the ink through the fibers.

- Coated finishes: The sandwich paper roll is coated with a layer of clay or polymer that produces a smoother base for the paper and enhances ink adhesion and sharpness of prints.

- Pre-Printing Coatings: Before printing on the paper we apply a barrier coating, for example, wax or grease-proof layers that shield the paper from penetration of oil and moisture.

- Post-Printing Coatings: After printing, various forms of varnish or laminates are applied to protect the printed design and give the paper a more high finish. These coatings improve the strength and effectiveness of paper in greasy or wet conditions.

Temperature Tolerance Of Custom Sandwich Paper

The temperature tolerance of custom sandwich paper depends largely on the type of paper and coatings used to manufacture it. As a sandwich paper wholesale manufacturer, we make sure that what you get from us can be useful in various conditions. Our sandwich wraps are capable of withstanding low temperatures of 20ºC most of which have a Wax or Grease proof layer making them ideal for cold or refrigeration products. Paper made from parchment or silicone-coated paper can withstand temperatures up to 220 degrees Celsius and can effectively wrap hot sandwiches or baked products.

Contact Us!

For a high-quality and attractive sandwich wrap with the ability to promote your brand, get the services of custom Greaseproof Papers. For a custom sandwich paper near me, simply go to our website and place your order in just a few simple steps and avail the best rates with premium quality for your custom papers.

Client Testimonials

Characteristics Of Our Custom Greaseproof Papers

Print your own

Custom paper in all sheet size

| 4" x 4" | 5" x 5" | 6" x 5" | 6" x 6" |

| 7" x 5" | 7" x 7" | 8" x 5" | 8" x 6" |

| 8" x 8" | 8.5" x 11" | 9" x 5" | 9" x 6" |

| 9" x 9" | 10" x 5" | 10" x 6" | 10" x 8" |

| 10" x 10" | 10.75" x 10" | 12" x 6" | 12" x 8" |

| 12" x 9" | 12" x 10" | 12" x 12" | 13" x 6" |

| 13" x 9" | 13" x 10" | 13" x 13" | 14" x 12" |

| 15" x 9" | 15" x 10.75" | 15" x 12" | 15" x 13" |

| 16" x 12" | 17" x 11" | 18" x 10" | 18" x 12" |

| 18" x 13" | 20" x 10" | 20" x 12" | 20" x 13" |

| 20" x 15" | 20" x 18" | 20" x 20" | 20" x 25" |

| 20" x 28" |

Welcome To

Greaseproof Papers

Join hands with our company to get all the different varieties of greaseproof papers

and enjoy amazing deals and excellent services in just a few clicks!