Custom Deli Paper

get an instant quote

STEP 1

UPLOAD YOUR LOGO

Upload vector image file – .pdf, .png, .jpg, or .eps vector graphic.

STEP 2

DESIGN YOUR PAPER

Adjust your logo or image in the design tool on the paper and design it.

STEP 3

SELECT PAPER CHOICES

Select paper size, print color(s), white or Kraft paper, and sheet quantity.

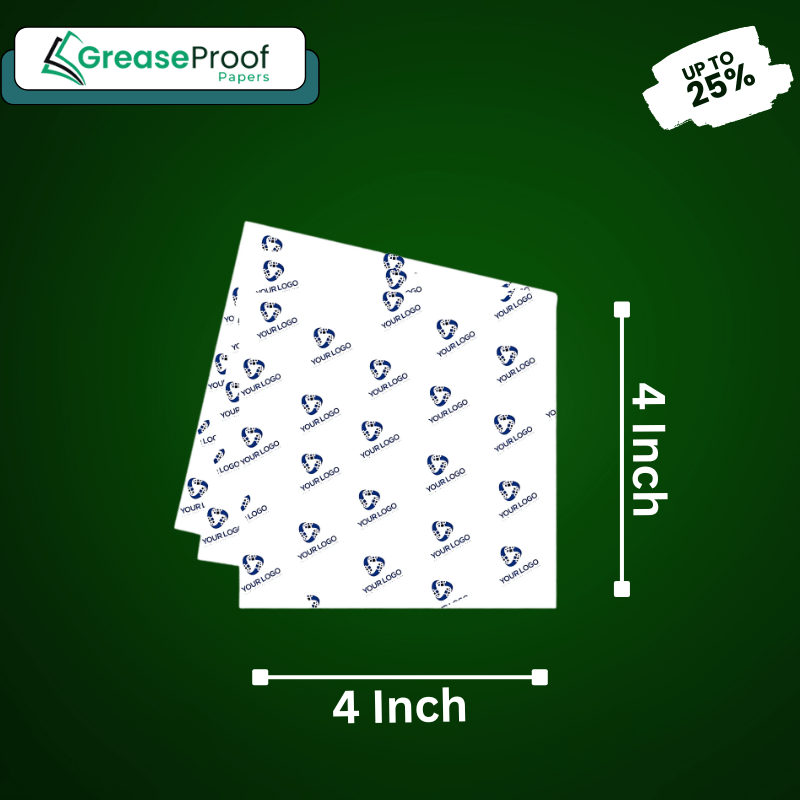

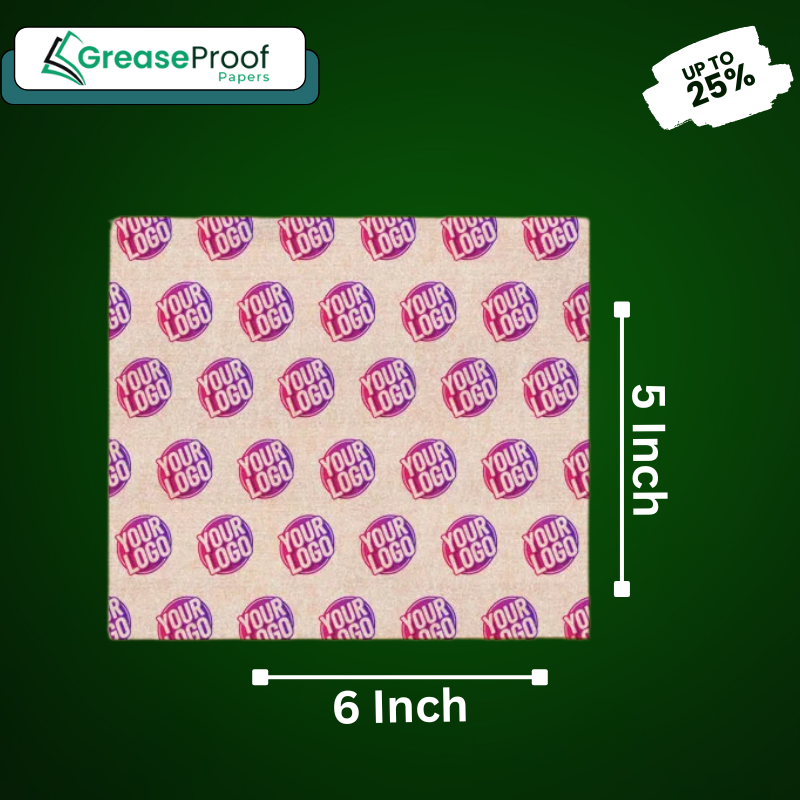

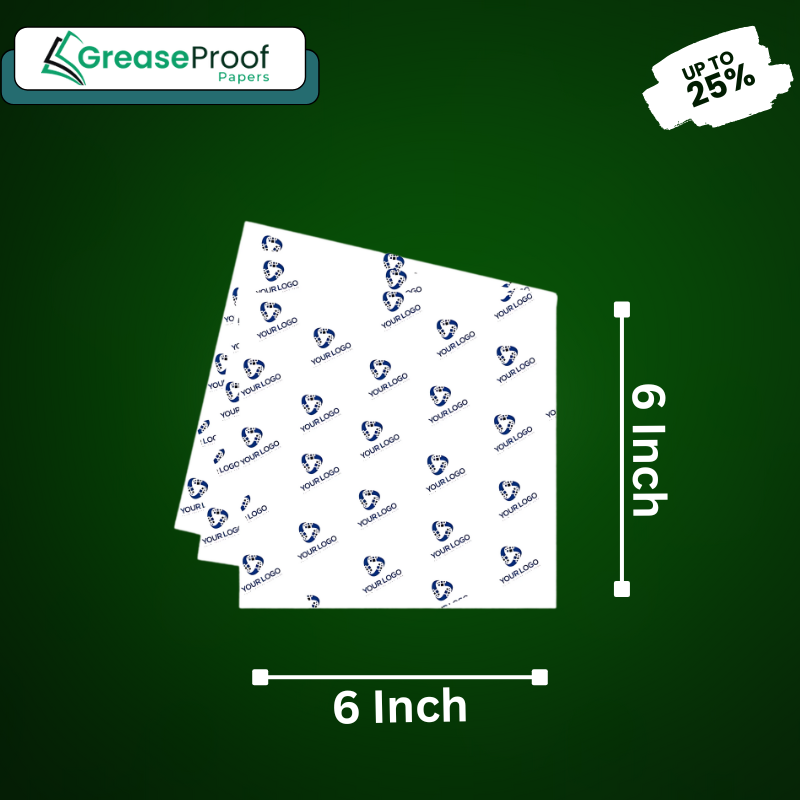

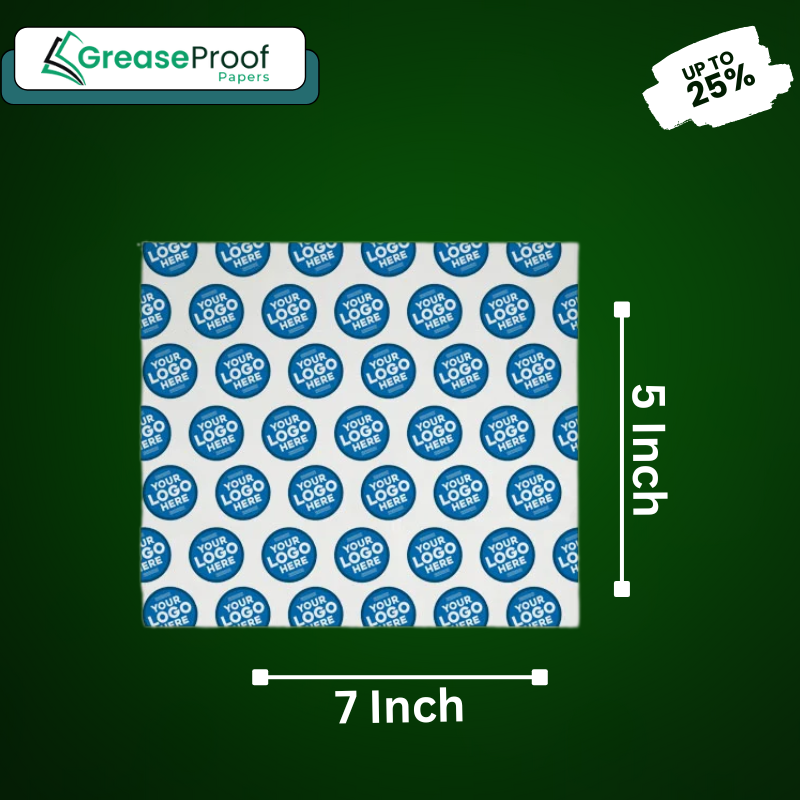

Products Size Variations

description

Custom Printed Deli Paper | Sustainable And Sturdy Choice

Your custom is far more than just packaging. It is a silent workhorse in both the culinary and commercial settings. In commercial settings, who can forget custom deli paper? This paper may look ordinary to you, but it is manufactured with precision to withstand grease and maintain structural integrity.

Unlike ordinary paper, this paper is designed to strike a balance between barrier protection and flexibility. The remarkable features of deli sheets make them an indispensable addition for deli stores and fast-serving restaurants.

Beyond food, the versatility of deli paper sheets extends to the industrial and retail sectors. At our company, we manufacture paper with the best available resources, which sets it apart from the rest of the packaging paper.

What is Deli Paper?

Custom printed paper for delis is a lightweight yet durable paper that is specifically designed for wrapping or serving food items. It is semi-translucent but has moisture and greasy residual qualities. It is an ideal option for displaying fresh items while maintaining their hygiene. We manufacture it through high-density pulp processing and combine its strength with a smooth finish.

Custom deli paper for restaurants and delis comes in sheets as well as rolls, according to the convenience of the customers. Prevention of oil and sauce seeping is the most defining trait of deli sheets without compromising the food presentation. These features make it one of the most technical staples across the food and packaging industry.

What Makes Deli Paper Different?

Custom deli paper bags and sheets are different from standard food wrapping. This paper is manufactured for mild grease and moisture resistance while retaining its breathability. Regular paper readily absorbs moisture and grease and becomes soggy.

As a custom deli paper wholesale provider, we refine the paper via a pulping process that enhances its barrier properties without adding thickness or making the paper stiff. The paper has a smoother texture, which prevents sticking and tearing during use.

Aside from this, deli paper is quite adaptable to printing and coatings while retaining its recyclable features. This makes the paper an excellent option for functional protection and marketing potential.

| Food Applications | Non-Food Applications |

| Burger Wrap | Candle Wrap |

| Sandwich Wrap | Soap Wrap |

| Bakery Wrap | Jewelry Wrap |

| Meat Serving | Surface Protect |

| Cheese Serving | Component Shipping |

| Pastry Serving | Glass Interleave |

| Basket Lining | Metal Interleave |

| Tray Lining | Plastic Interleave |

| Container Lining | Craft Use |

| Food Separation | Decorative Packaging |

Material and Technical Features

While you are going to select custom deli paper online, you have to keep in mind several factors. For instance, the GSM of the paper must be 25 to 45 so that it remains lightweight while structurally resilient. Refined wood pulp undergoes pulping and is combined with sizing agents to enhance the grease resistance properties of the paper. The common features the high-end pulping process gives to the paper are as follows:

- High wet-strength

- Low porosity

- Controlled absorbency that prevents oil migration

The paper has a semi-crystalline cellulose structure that makes it stable under hot and cold conditions. These special features enable deli paper sheets to perform reliably across diverse applications.

Printing Methods And Retention Of Sustainability

Flexography is one of the most common methods used to print deli paper sheets due to its adaptability with water-based inks and its ability to handle large volumes. On the other hand, the selection of offset printing gives high-resolution branding, but it is not very potent with paper sheets. For custom and small orders, we prefer to give our customers the option of digital printing.

To retain the sustainability of paper, we use soy or water-based inks for custom deli paper printing. These inks are free from harmful residues and allow the recyclability of paper. Today, all customers prefer sustainable paper. So by avoiding the use of heavy solvent-based coatings and inks, we can retain the compostable attributes of deli sheets.

If you also want to grab the attention of customers in the USA and want to become a responsible food brand in the crowded market of the United States, then it’s high time you start investing in our packaging paper. So if you are looking for an answer to how to print on deli paper while retaining its sustainability, then the best answer is the use of sustainable inks.

Coatings To Enhance Resistance

Coatings are applied on custom deli paper with a logo without transferring it to wax paper or parchment paper. The common coatings that we use are:

- Aqueous dispersion coatings

- Polyethylene (PE) laminations in micro-thicknesses

- Biodegradable polymer films

These coatings reduce the porosity of the paper and enhance the oil resistance capacity while extending the shelf life of the paper. Aqueous coating forms a thin layer over the surface of custom paper sheets for deli stores and easily breaks down during the recycling process. On the other hand, biopolymer coatings give grease-proofing ability while retaining the compostable aspect of the paper.

We apply the coatings in controlled weights by measuring them in gsm. This helps in the retention of the lightweight nature and tactile feel of deli rolls. We give “custom deli paper no minimum”, which allows you to choose the paper quantity based on your requirement, and there is no distinction between the MOQs of different coatings on the paper. As we do everything via our advanced manufacturing facility, we make sure that the paper remains distinct from heavier specialty paper, no matter what coating is applied.

Identification Via Touch And Feel

If you are searching for “custom deli paper near me,” then one thing you want to know is the identification of the right deli paper. In the USA, you will find plenty of options for the paper. This diversity sometimes makes it difficult to select the right options. So you must have an idea of the texture of the paper so that you can select the right deli sheets for your company.

Deli paper is dry and smooth with a slight crisp texture. It is semi-translucent and appears visually different from opaque paper sheets, such as glassine paper. When you touch the paper, it will give subtle resistance that prevents slipping and is useful for wrapping greasy food. When you compare the paper with parchment sheets, you will feel that deli paper sheets are more flexible and are less stiff. The lightweight GSM of the paper makes it sound sharp. These are the few features that one must keep in mind while looking for custom deli paper cheap but of high quality.

Molecular And Chemical Attributes

At the molecular level, deli paper is composed of cellulose fibers. These fibers have a semi-crystalline structure that imparts the paper strength and flexibility. The hydrogen bonding between the cellulose chains provides tensile strength. We also incorporate sizing in a controlled manner that alters surface energy and resists the grease penetration in the sheet.

Chemically, this paper has low porosity and a balance of hydrophilicity that prevents the absorption of oils while retaining breathability. To enhance the moisture and grease resistance of paper, we use alkyl ketene dimer (AKD) or rosin sizing as additives. Overall, the chemical profile of deli paper is inert, which makes it non-toxic and biodegradable, so that you can use it in direct contact with the food.

Call Now!

Get your custom deli paper printed with your branding elements and give your customers an amazing experience with your brand. At Greaseproof papers, we are determined to deliver quality without incurring high cost. Our company believes in diversity and gives all the food brands in the USA unique and custom options for papers. So book your quote and start excelling!

Client Testimonials

Characteristics Of Our Custom Greaseproof Papers

Print your own

Custom paper in all sheet size

| 4" x 4" | 5" x 5" | 6" x 5" | 6" x 6" |

| 7" x 5" | 7" x 7" | 8" x 5" | 8" x 6" |

| 8" x 8" | 8.5" x 11" | 9" x 5" | 9" x 6" |

| 9" x 9" | 10" x 5" | 10" x 6" | 10" x 8" |

| 10" x 10" | 10.75" x 10" | 12" x 6" | 12" x 8" |

| 12" x 9" | 12" x 10" | 12" x 12" | 13" x 6" |

| 13" x 9" | 13" x 10" | 13" x 13" | 14" x 12" |

| 15" x 9" | 15" x 10.75" | 15" x 12" | 15" x 13" |

| 16" x 12" | 17" x 11" | 18" x 10" | 18" x 12" |

| 18" x 13" | 20" x 10" | 20" x 12" | 20" x 13" |

| 20" x 15" | 20" x 18" | 20" x 20" | 20" x 25" |

| 20" x 28" |

Welcome To

Greaseproof Papers

Join hands with our company to get all the different varieties of greaseproof papers

and enjoy amazing deals and excellent services in just a few clicks!

Related Products

FAQs (Frequently Asked Questions)

Custom deli paper is commonly used to wrap sandwiches, cheese slices, burgers, etc at deli stores, restaurants, and cafes. This paper with tissue-like consistency keeps the packed items fresh and safe from getting soggy.

Yes, our custom printing options allow us to print any unique designs and artwork on paper.

Yes, this paper is made from food-grade material which makes it suitable for direct contact with the food sites.

You can get any size of paper to accommodate your product because various types of foods need different sizes of paper so we do not put any restrictions on the size of the paper.

Yes, you can use deli paper for other reasons too such as lining trays, in arts and crafts, to wrap gifts, etc.

We both use the type of deli paper. The difference relies on the type of coating applied to the paper. Greaseressant deli paper is the one that can resist grease, but to a limited extent. On the other hand, grease-proof paper is coated with high-end wax or polyethylene. This paper can withstand food with high fat content.

At your company, you will find a diverse range of sizes and styles from pre-cut sheets to rolls and paper bags. We have everything at your disposal in the preferred size of your brand. However, the common sizes that customers prefer are as follows:

Common Sizes for Wrapping Sandwiches

- 6″ x 6″ (15 x 15 cm): Small sandwiches or half wraps

- 10″ x 10″ (25 x 25 cm): Standard deli-style sandwiches

- 12″ x 12″ (30 x 30 cm): Large or overstuffed sandwiches

Common Sizes for Wrapping Burgers

- 10″ x 10″ (25 x 25 cm): Regular burgers

- 12″ x 12″ (30 x 30 cm): Large burgers or double patties

- 15″ x 15″ (38 x 38 cm): Oversized or gourmet burgers

Yes, you can use the paper as an alternative to the tray and basket liners. Deli papercano retains a moderate amount of grease while allowing a significant level of breathability.

Yes, you can print on both sides of the paper, but it will increase the cost and may require certain precautionary measures while manufacturing. The type of coatings applied to the paper is one of the important factors that determine the printability of the sheet.

At our company, all the features of the paper are selected based on the customer’s requirements. So it depends on you what you want, sheets or rolls. We have all the sizes and styles for you.